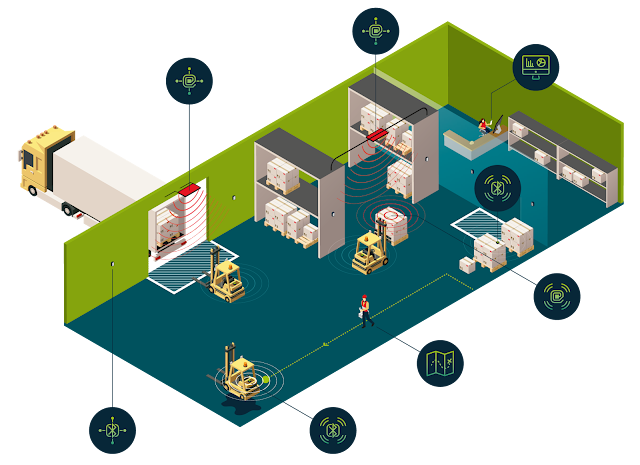

Asset tracking is a flexible management strategy that should be implemented by business for effective facility management and outcomes. Enterprises that invest in asset tracking of their portable and fixed asset record higher returns compared to enterprises that don’t. Apart from improved asset management, asset tracking simplifies the tedious monitoring process and ensures proper and timely allocation of assets during the firm operations

Here are 5 benefits a firm enjoys through asset tracking for improved and effective facility management.

1. Asset Location

Developments in asset tracking software have enabled accessing of real-time information on the location of the specific assets. These assets could be in the firm premises or in transits. A delivery company access to the location of a certain asset can note if it arrived at the required destination and enables record keeping for future reference. Asset location has been a major factor to the growth of freight investments. One can order cargo, delivery services, and shipment services online and track the movement of the freight.

One should consider the best tracking software that provides a wide range tracking coverage for different assets. A good example is when you Track your assets with TrackAbout Software, you are able to select from their wide tracking services on different assets. These assets range from delicate gas cylinders and medical equipment to containers and tools.

2. Timely Replacement/Fix Decisions

Asset tracking enables setting of specific performance limits in different used assets in the farm. It tracks and gives warning signals to the operators when facility operational limits are exceeded. The warning signals enable timely replacement of assets or fixing the assets to their normal operational status. These prevent asset destruction hence continuity in performance. A good example is monitoring oil leakage in transits vehicles. A warning signal will be generated and the driver will respond by the timely fixing of the problem to prevent later severe repercussions. Through early warning services, one will never be surprised by machinery breakdown. It gives the manager the advantage of being a step ahead.

3. Detailed report on equipment performance

Equipment performance information is simply acquired through effective equipment tracking. Equipment performance is a major factor in why facility management is important. Through the easily accessible history records available on the website, the management of a business can easily identify incidents where equipment faced downtime, determine the root cause, and apply the necessary resolutions. This ensures improved future performance hence saves money and time.

4. Improved Purchasing Decisions

Through proper evaluation of asset tracking reports, a firm will be well informed on their immediate and future purchases. When the tracking report reveals worn out parts of equipment, the management will carry out an early purchase of relevant spare parts. This will give the management ample time to get the best spare parts instead of panic purchases and impulse buying.

5. Accuracy in Repair

Asset tracking reviles the specific part of a building or a machine that requires repair for continual in functionality. It enables the management to get the right equipment and the right contractors to repair the issue. These save time as the contractors know the specific focal area.

In conclusion, asset tracking plays a major role in ensuring proper facility management. The 5 major benefits derived from asset tracking include; asset location, timely decision making in fixing and replacement of facilities, a detailed report on equipment performance record, improved purchasing decisions, and accuracy in repair.

Here are 5 benefits a firm enjoys through asset tracking for improved and effective facility management.

1. Asset Location

Developments in asset tracking software have enabled accessing of real-time information on the location of the specific assets. These assets could be in the firm premises or in transits. A delivery company access to the location of a certain asset can note if it arrived at the required destination and enables record keeping for future reference. Asset location has been a major factor to the growth of freight investments. One can order cargo, delivery services, and shipment services online and track the movement of the freight.

One should consider the best tracking software that provides a wide range tracking coverage for different assets. A good example is when you Track your assets with TrackAbout Software, you are able to select from their wide tracking services on different assets. These assets range from delicate gas cylinders and medical equipment to containers and tools.

2. Timely Replacement/Fix Decisions

Asset tracking enables setting of specific performance limits in different used assets in the farm. It tracks and gives warning signals to the operators when facility operational limits are exceeded. The warning signals enable timely replacement of assets or fixing the assets to their normal operational status. These prevent asset destruction hence continuity in performance. A good example is monitoring oil leakage in transits vehicles. A warning signal will be generated and the driver will respond by the timely fixing of the problem to prevent later severe repercussions. Through early warning services, one will never be surprised by machinery breakdown. It gives the manager the advantage of being a step ahead.

3. Detailed report on equipment performance

Equipment performance information is simply acquired through effective equipment tracking. Equipment performance is a major factor in why facility management is important. Through the easily accessible history records available on the website, the management of a business can easily identify incidents where equipment faced downtime, determine the root cause, and apply the necessary resolutions. This ensures improved future performance hence saves money and time.

4. Improved Purchasing Decisions

Through proper evaluation of asset tracking reports, a firm will be well informed on their immediate and future purchases. When the tracking report reveals worn out parts of equipment, the management will carry out an early purchase of relevant spare parts. This will give the management ample time to get the best spare parts instead of panic purchases and impulse buying.

5. Accuracy in Repair

Asset tracking reviles the specific part of a building or a machine that requires repair for continual in functionality. It enables the management to get the right equipment and the right contractors to repair the issue. These save time as the contractors know the specific focal area.

In conclusion, asset tracking plays a major role in ensuring proper facility management. The 5 major benefits derived from asset tracking include; asset location, timely decision making in fixing and replacement of facilities, a detailed report on equipment performance record, improved purchasing decisions, and accuracy in repair.

No comments:

Post a Comment